If you’re a technology enthusiast or engineer looking to expand your knowledge in the world of Distributed Control Systems (DCS), you’ve come to the right place. In this article, we will introduce you to the Yokogawa Centum VP, one of the most popular DCS systems on the market.

Contents

Understanding DCS: The Basics

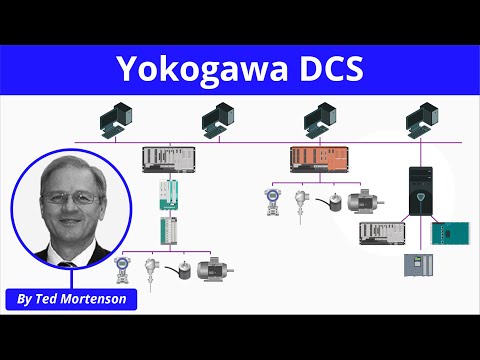

Before delving into the details of the Yokogawa Centum VP, let’s take a moment to understand the basic structure and components of a typical DCS. A DCS is a computerized control system consisting of multiple autonomous controllers that operate and control various control loops. Unlike other control systems, a DCS doesn’t have centralized supervisory control, hence the name “Distributed” Control.

In a DCS, field devices are connected to I/O modules located in cabinets alongside controllers. These controllers communicate with each other using various communication protocols such as Ethernet, Modbus, or proprietary protocols. Additionally, there are operator stations (HMI) located in a centralized control room or elsewhere, providing plant operators real-time access to observe and adjust plant conditions. Engineering stations (HMI) are also present, allowing control logic programming changes for the system’s control loops.

Yokogawa: A Legacy in Industrial Automation

Yokogawa, a Japanese industrial company, has been at the forefront of industrial automation since 1915. The company initially started with the manufacture and sales of electric meters and has since become a leading provider of advanced automation solutions. In 1975, Yokogawa introduced its first CENTUM DCS, paving the way for subsequent advancements in control systems.

Introducing Yokogawa Centum VP

The Yokogawa Centum VP, released in 2014, is the latest version of their flagship DCS offering. It boasts a comprehensive system architecture that ensures seamless plant process control. The system comprises various components, including the Human Interface Station (HIS), Field Control Station (FCS), and more.

System Architecture of Yokogawa Centum VP

Yokogawa refers to the Human Interface Station (HIS) as an HMI. The HIS is primarily used for operations, but additional stations can be configured for engineering purposes. The Field Control Station (FCS) is responsible for providing actual plant process control. All process information is placed on the control network called Vnet/IP, to which all CENTUM devices are connected.

The Yokogawa Centum VP is designed to communicate with a variety of network-based subsystems through the Unified Gateway Station (UGS). This allows integration with Modbus RTUs, Modbus/TCP units, EtherNet/IP units, and other external systems. Network switching is handled by layer switches, such as L2SW, which refers to a layer 2 switch. The Vnet/IP transmission media can be fiber optic or Unshielded Twisted Pair cables, operating at one Gigabit per second.

The CENTUM VP system utilizes a Vnet/IP domain, consisting of two separate subnets, namely bus 1 and bus 2, each capable of accommodating up to 64 stations. Communication between the two domains is facilitated by an L3SW switch. The Field Control Station (FCS) houses the Power Supply, Controller, and Field Input/Output (FIO) modules, including analog, digital, and communication modules.

Safety Features: ProSafe-RS SIS

In addition to the Yokogawa Centum VP DCS, Yokogawa offers a Safety Instrumented System (SIS) called ProSafe-RS. This system conforms to Safety Integrity Level SIL3, as defined by IEC 61508. The ProSafe-RS SIS comprises components that are visually distinct, being a bright orange color, ensuring easy identification and differentiation from the rest of the system.

Enhancing Operational Efficiency with PRM and Automation Design Suite

Yokogawa’s Plant Resource Manager (PRM) is an asset management software package that enables the diagnostic capabilities of smart devices. It facilitates the integration of devices using HART or Profibus communication protocols into the DCS system, providing enhanced control and maintenance capabilities.

The Automation Design Suite is Yokogawa’s engineering software, which simplifies the creation of plant graphics for Operator HIS terminals. These graphics assist operators in visualizing plant conditions, making it easier to monitor and control various processes.

FAQs

Here are some frequently asked questions about Yokogawa Centum VP:

-

What is the Yokogawa Centum VP?

The Yokogawa Centum VP is a highly regarded Distributed Control System (DCS) that offers comprehensive plant process control. -

What is the ProSafe-RS SIS?

The ProSafe-RS SIS is a Safety Instrumented System (SIS) provided by Yokogawa, offering enhanced safety features for industrial plants. -

What is the significance of the Yokogawa PRM?

Yokogawa PRM is an asset management software package that enables diagnostic capabilities for smart devices and enhances control and maintenance capabilities.

Conclusion

With over a century of experience in the field of industrial automation, Yokogawa has continually evolved to provide cutting-edge control solutions. The Yokogawa Centum VP DCS, with its comprehensive system architecture, safety features, and advanced engineering software, ensures efficient and reliable plant process control. To learn more about the Yokogawa Centum VP and other related topics, visit Techal.