In the world of industrial processes, operator control plays a crucial role in ensuring smooth operations and minimizing risks. And at the heart of operator control lies the Human Machine Interface (HMI) – a graphical representation of the process that allows operators to interact with and monitor the system.

While the concept of an HMI seems straightforward, the reality is that many HMIs are poorly designed, leading to compromised safety, decreased productivity, and lower profitability. This is where High-Performance HMI comes into play.

Contents

The Need for High-Performance HMI

High-Performance HMI is the industry’s answer to addressing the shortcomings of traditional HMIs. It provides a standardized, easy-to-use, and more productive graphics system that can either complement or replace poorly designed HMIs.

The Consequences of Poorly Designed HMIs

Poorly designed HMIs can result in a host of problems. Operators might resort to “running by the alarms,” where they only respond to alarms without understanding the underlying issues. This can lead to poor operating procedures and suboptimal responses to abnormal situations. In the worst cases, a poorly designed HMI has even contributed to industrial accidents.

The Evolution of HMIs

Early HMIs were simplistic representations of the process they controlled, limited by the computing and graphics power of their time. However, as technology advanced, the prevailing mindset shifted towards highly complex, data-filled, and visually striking HMIs. This led to a proliferation of inconsistent and confusing displays, varying from system to system.

Introducing High-Performance HMI

In 2003, the International Society of Automation (ISA) assembled a group of end-users, operators, and engineers to develop a standardized approach to HMI design. After twelve years of collaboration, the group published the “ISA101 HMI Design Standard” in 2015. This standard serves as a set of guidelines, principles, and philosophies for developing graphics on process HMIs.

Key Concepts of High-Performance HMI

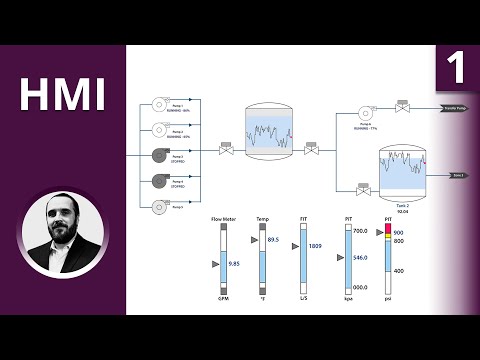

High-Performance HMI introduces several key concepts to enhance operator control and situational awareness.

Proper use of Colors

High-Performance HMIs are developed primarily in grayscale, with color strategically used to draw attention to abnormal situations. The new use of color alone has shown a 48% improvement in detecting abnormalities before alarms occur.

Information over Data

Instead of overwhelming operators with numerous data points, High-Performance HMIs prioritize providing meaningful information. By utilizing indicators, operators can quickly understand whether a process variable is within an acceptable range or not.

Trends for Quick Evaluation

High-Performance HMIs incorporate embedded or always-visible trend displays for crucial process variables. These trends allow operators to evaluate historical data quickly and make necessary adjustments before issues arise.

Simplicity and Uncluttered Screens

High-Performance HMIs focus on simplicity and clarity. Rather than bombarding operators with unnecessary visual elements, HMIs present only essential information using standard symbols and intuitive navigation buttons.

Display Hierarchy

A hierarchical system of displays is critical for achieving situational awareness. High-Performance HMIs employ a four-level hierarchy:

- Level 1: Provides an overall view of the process.

- Level 2: Offers a smaller, more detailed perspective.

- Level 3: Focuses on specific equipment details.

- Level 4: Accesses detailed troubleshooting information.

FAQs

Q: Where can I learn more about High-Performance HMI?

A: For more in-depth information on High-Performance HMI, refer to the High-Performance HMI handbook, a valuable resource that delves further into this topic.

Q: How can High-Performance HMI improve productivity and safety?

A: By implementing High-Performance HMI, operators can benefit from standardized models that improve productivity, enhance quality, and increase safety.

Conclusion

High-Performance HMI represents a significant advancement in operator control and safety. By following standardized design principles and incorporating key concepts such as proper use of color, information-driven displays, and simplified screens, High-Performance HMIs empower operators to make informed decisions efficiently. While High-Performance HMI continues to evolve, embracing these principles paves the way for improved productivity, quality, and safety in industrial processes.

Thank you for reading this article! If you’d like to learn more about the world of technology, visit Techal for informative content and comprehensive guides.