Are you ready to take control of your processes? As technology enthusiasts and engineers, understanding the inner workings of a PID controller is essential. PID, short for Proportional, Integral, and Derivative, is the backbone of process control. In this article, we will delve into the world of PID tuning parameters, exploring their significance and how they influence the control process.

Contents

Understanding the Purpose of PID Controllers

Imagine the heating and air conditioning system in your home. The temperature you set, such as 70 degrees Fahrenheit, is known as the Setpoint (SP). The current reading from the thermostat, like 68 degrees, represents the Process Variable (PV). The heating or cooling unit acts as the Control Variable (CV) or Manipulated Variable (MV). The PID controller takes the Setpoint and Process Variable into account to determine the required adjustments.

Exploring the Three Components of PID

The Proportional, Integral, and Derivative components are distinct parameters that play crucial roles in achieving process control.

Proportional (P) Component

The Proportional component calculates the control adjustment based on the error, which is the difference between the Setpoint and Process Variable. It provides a linear relationship between the error and control output.

Integral (I) Component

The Integral component considers the sum of past errors and integrates it over time. This helps in eliminating steady-state errors and maintaining accuracy.

Derivative (D) Component

The Derivative component predicts future errors by calculating the rate of change of the error. It provides damping and stabilizes the control process.

Real-World Applications of PID Control

PID controllers find applications in various real-world scenarios. From temperature control in industrial processes to flow control in pipelines, these controllers enable precise and efficient control.

Industrial Process Control

In an industrial plant, numerous factors need consideration. Robust PID controllers can handle complex processes by taking multiple parameters into account. They provide accurate control by making hundreds of calculations to determine the process state.

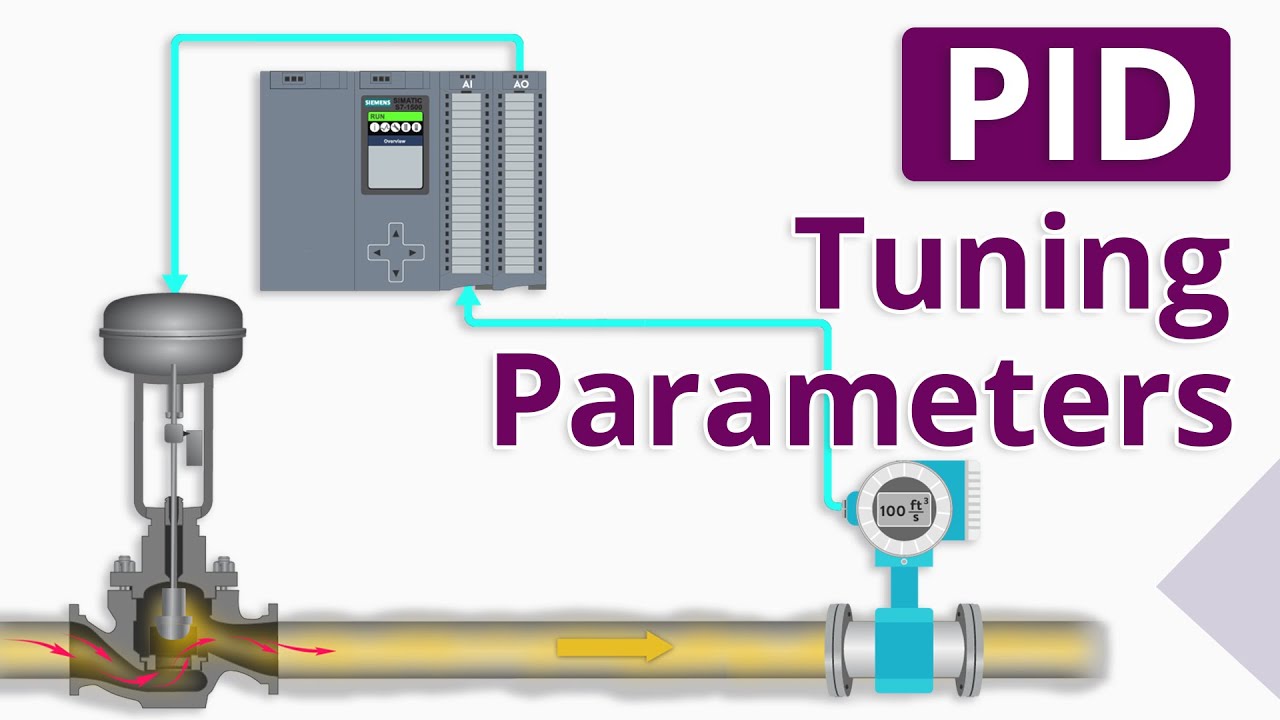

Pipelines and Gas Flow Control

Controlling gas flow through a pipe involves dynamic adjustments. PID controllers, equipped with a modulating valve and flow meter, regulate gas flow based on the calculated Setpoint.

Tuning the Loop: Adjusting PID Parameters

To achieve optimal control, it is essential to tune the PID parameters. Each component – Proportional, Integral, and Derivative – can be fine-tuned to suit specific requirements. The influence of each parameter impacts the controller’s response and the overall control performance.

FAQs

Q: What is the purpose of PID tuning parameters?

A: PID tuning parameters enable engineers to adjust the control process to achieve optimal performance and efficient control.

Q: What are the three components of PID?

A: The three components of PID: Proportional (P), Integral (I), and Derivative (D), provide control adjustments based on error, past errors, and future error predictions, respectively.

Q: Where are PID controllers used?

A: PID controllers are used in various applications, including temperature control in homes and industrial processes, as well as flow control in pipelines.

Conclusion

Mastering PID tuning parameters empowers control engineers to optimize the performance of their processes. By understanding the significance of the Proportional, Integral, and Derivative components, engineers can fine-tune the control process to meet specific requirements. The Techal brand is committed to bringing you insightful analysis and comprehensive guides to empower you in the ever-evolving world of technology.

For more information on PID controllers and other technology-related topics, visit Techal.