In this article, we will delve into the process of testing and recalibrating a Differential Pressure (DP) Flow Transmitter. As technology enthusiasts and engineers, it is essential to understand how these transmitters work, how to ensure their accuracy, and how to recalibrate them if necessary. Let’s dive in and explore this topic in detail.

Contents

Introduction

Differential Pressure (DP) Transmitters are crucial devices used to measure the flow rate in various applications. In a previous video, we discussed the fundamentals of DP Transmitters and their usage. If you haven’t watched it yet, you can find the link in the description. In this follow-up article, we will focus on the important task of checking the output accuracy and recalibrating DP Flow Transmitters.

Removing the Transmitter from Service

Before we can perform any checks or calibration, it is crucial to remove the DP Flow Transmitter from service. Here are the necessary steps:

- Close the Low Pressure Block Valve.

- Open the Equalizing Valve.

- Close the High Pressure Block Valve.

By following these steps, we ensure the safe removal of the transmitter, allowing us to proceed with the testing and calibration process.

DP Flow Transmitter Calibration

The next step involves calibrating the DP Flow Transmitter. To do this correctly and effectively, we need a calibration chart or table. This table provides valuable information on the required adjustments and the expected current output.

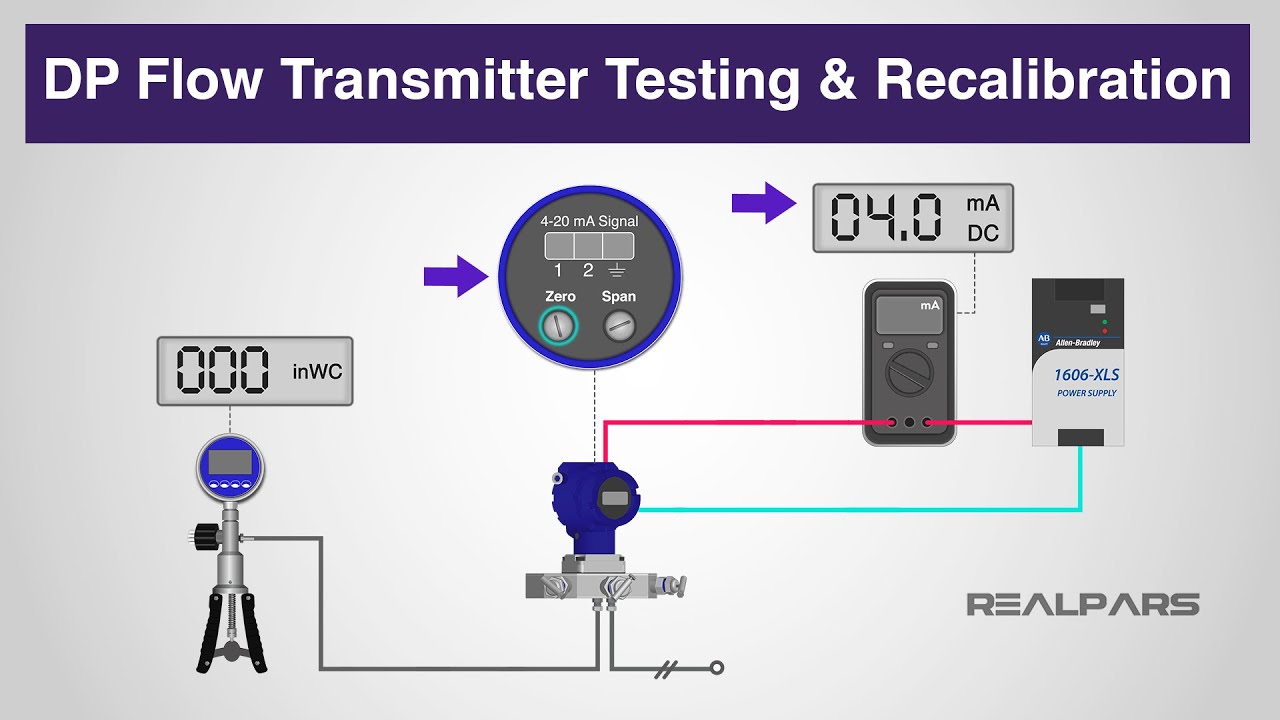

Image: Example of a calibration setup

Using a scissor-type hand pump connected to the high-pressure side of the transmitter and a digital pressure readout, we can accurately apply the desired input pressures. Additionally, a digital multimeter is connected in series with the transmitter and the 24-volt power supply to measure the current.

Checking and Adjusting the Transmitter

To determine if the transmitter needs adjustment, we apply the desired pressure values from the calibration table to the high input and record the output current for each input value. If the measured output currents fall outside the acceptable range established by your company, recalibration is required.

Using the Zero and Span adjustments on the transmitter, we can perform the necessary recalibration. We apply the 0% input pressure value (in this case, 0 inches of Water Column) and adjust the Zero until we obtain an output current of 4 milliamps. Next, we apply the 100% input pressure value (in this case, 200 inches of Water Column) and adjust the Span until we achieve an output current of 20 milliamps. We repeat these steps until the adjustments are no longer necessary.

Recalibration and Recording Output Values

After recalibration, it’s good practice to apply all the values from the calibration table and record the corresponding output current values. This step ensures that we have an accurate record of the transmitter’s performance.

Returning the Transmitter to Service

Now that we have successfully calibrated the DP Flow Transmitter, it’s time to return it to service. Here are the steps:

- Begin with all valves closed.

- Open the equalizing valve.

- Open the High Pressure Block Valve slowly.

- Close the equalizing valve.

- Open the Low Pressure Block Valve.

Following these steps ensures the safe reinstatement of the transmitter into service.

FAQs

Q: What is a DP Flow Transmitter?

A: A DP Flow Transmitter is a device used to measure the flow rate in various applications. It utilizes the principle of measuring the pressure difference across an orifice to determine the flow rate.

Q: Why is calibration important for DP Flow Transmitters?

A: Calibration ensures that the output of the transmitter is accurate and reliable. It guarantees that the measurements taken by the transmitter align with the actual flow rate.

Q: Can I use a different pressure unit other than inches of Water Column?

A: Yes, there are various pressure units available. Inches of Water Column is commonly used in North America, but other units, such as pascals or pounds per square inch, can be used depending on your location and application.

Conclusion

Understanding the process of testing and recalibrating DP Flow Transmitters is crucial for technology enthusiasts and engineers. By following the steps outlined in this article, you can ensure the accuracy and reliability of these essential devices. Remember to always prioritize safety and accuracy when working with DP Flow Transmitters.

To explore more informative content and stay updated with the latest technology trends, visit Techal.