Profibus is a widely used industrial communication protocol that allows devices such as sensors, actuators, and controllers to communicate with each other in real-time. It offers two main variants: Profibus-DP and Profibus-PA. In this article, we will explore the differences between the two and understand their unique features.

Contents

Introduction

Imagine a factory with a control room filled with industrial computers, and a factory floor with multiple sensors. The industrial computers, known as programmable logic controllers (PLCs), monitor the sensors to control the manufacturing process. However, in large factories, the distance between the control room and the sensors can be significant, leading to challenges in connectivity.

Profibus-DP: Decentralized Peripherals

Profibus-DP (Decentralized Peripherals) is a solution that tackles the connectivity issue between PLCs and sensors. Instead of running multiple cables from the control room to the factory floor, Profibus-DP allows you to move the PLC inputs and outputs (I/Os) to the factory floor and connect them to the sensors using a single RS-485 cable. This setup is cost-effective and efficient, as it reduces the number of cables required.

Profibus-PA: Process Automation

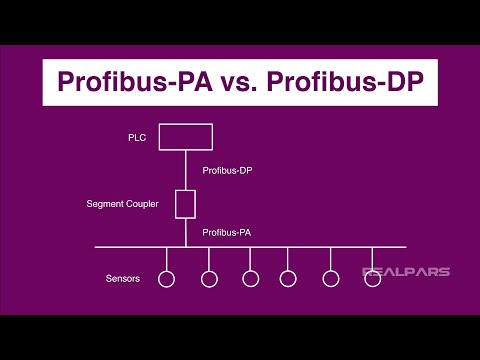

Profibus-PA (Process Automation) takes the efficiency one step further by eliminating the need for I/O units and multiple cables. Instead, a single Profibus-PA bus connects all the sensors, and a segment coupler converts the Profibus-PA signal to the Profibus-DP signal that the PLC understands. This setup significantly reduces costs and simplifies the network structure.

FAQs

Q: Can I connect Profibus-PA directly to the PLC?

A: No, the PLC does not have a Profibus-PA port. However, most PLCs have a Profibus-DP port. By using a segment coupler or converter, you can integrate Profibus-PA into existing systems with a Profibus-DP port.

Q: How do Profibus-DP and Profibus-PA improve PLC controls?

A: Profibus-DP allows for decentralized I/Os, reducing the number of cables required. Profibus-PA goes a step further by replacing I/O units and cables with a single Profibus-PA bus, resulting in a more efficient and economical network structure.

Conclusion

Profibus-DP and Profibus-PA have revolutionized the ease and efficiency of setting up PLC controls in industrial environments. By decentralizing I/Os and utilizing different bus structures, these communication protocols have simplified connectivity and reduced costs. Whether you opt for Profibus-DP or Profibus-PA depends on the specific requirements of your application. To learn more about industrial automation topics, visit Techal.