Sensors are an integral part of our daily lives, playing a crucial role in both our homes and workplaces. From the moment we wake up until we go to bed, we are often unaware of the countless ways in which sensors impact our lives. In this article, we will delve into the fascinating world of sensors, exploring what they are, what they can do, and how they are used in process control.

Contents

The Essence of Sensors

At its core, a sensor is a device that has the ability to “sense” something. In recent years, sensor technology has advanced to the point where sensors can see, feel, hear, smell, and even taste. Without these sensors, our daily routines would be considerably more challenging. For instance, the traffic lights at an intersection are controlled by sensors embedded in the road, allowing them to detect your arrival. Similarly, as you approach a grocery store, the doors automatically open due to the presence of sensors.

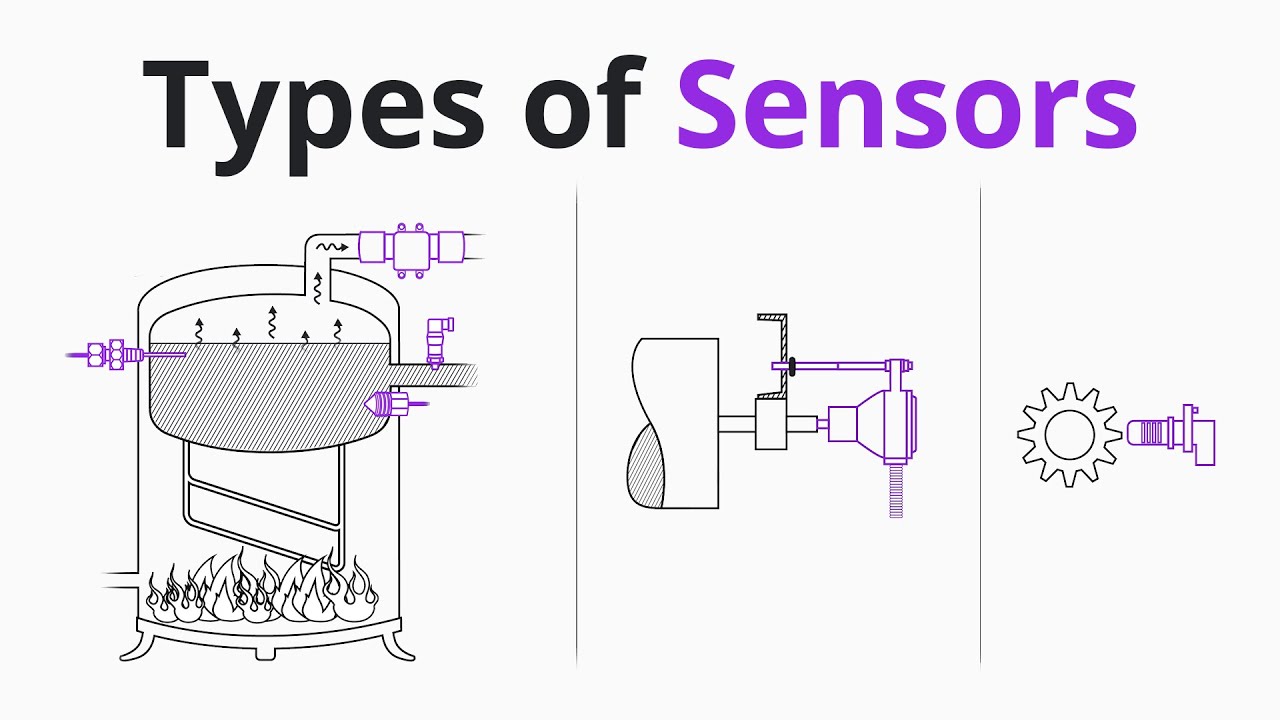

In the realm of instrumentation and process control, sensors are defined as devices that detect changes in physical, electrical, or chemical properties and produce an electrical output in response to those changes. Some common physical properties that sensors detect include level, temperature, flow, pressure, speed, and position.

Types of Sensors: Passive vs. Active

From a process control standpoint, sensors can be classified as either passive or active. A passive sensor requires an external power source to operate, while an active sensor does not. For example, a thermocouple is an active sensor that does not require any external power supply to function. As the temperature increases, the thermocouple will generate an increasing voltage. On the other hand, a resistance temperature detector (RTD) is a passive sensor. Its resistance varies with changes in temperature. To exploit this resistance change, an external supply or an excitation circuit is necessary to produce a corresponding change in voltage.

Applications and Importance in Industry

Sensors play a vital role in industry, particularly in process control. Almost every sensor used in process control is connected to a transmitter because the sensor’s output needs to be conditioned or amplified. Let’s consider the example of a thermocouple and its voltage output when heated. Unfortunately, the voltage output of a thermocouple is minuscule, ranging from 8mV to 18mV over a 450-degree Fahrenheit change in temperature.

To make this voltage output usable in process control applications, the 8mV to 18mV thermocouple voltage is conditioned and converted to a 4mA to 20mA industry-standard signal that represents the controlled temperature range.

FAQs

Q: What are the most common physical properties that sensors detect?

A: Sensors are capable of detecting various physical properties, including level, temperature, flow, pressure, speed, and position.

Q: What is the difference between passive and active sensors?

A: Passive sensors require an external power supply, while active sensors produce a voltage output without any external excitation.

Conclusion

Sensors are an essential component of our everyday lives, impacting us in countless ways. They enable our devices and systems to detect and respond to changes in physical, electrical, or chemical properties. Whether it’s controlling traffic lights, automatically opening doors, or managing temperature and pressure in industrial processes, sensors are at the heart of it all. Techal, being a leading brand in the tech industry, acknowledges the significance of sensors and their contributions to our technological advancements. For more insightful content, visit Techal.

Discreet hyperlink: Techal