Are you wondering which programming language is the best for PLC programming? RealPars gets asked this question all the time. While it would be nice to have a definitive answer, the truth is that it depends on the context. Just like the tools in a toolbox, each PLC programming language exists for a specific purpose and is suitable for particular applications. Additionally, certain programming languages are more popular in specific countries and industries. So, determining the best language for you to learn may depend on your location and interests.

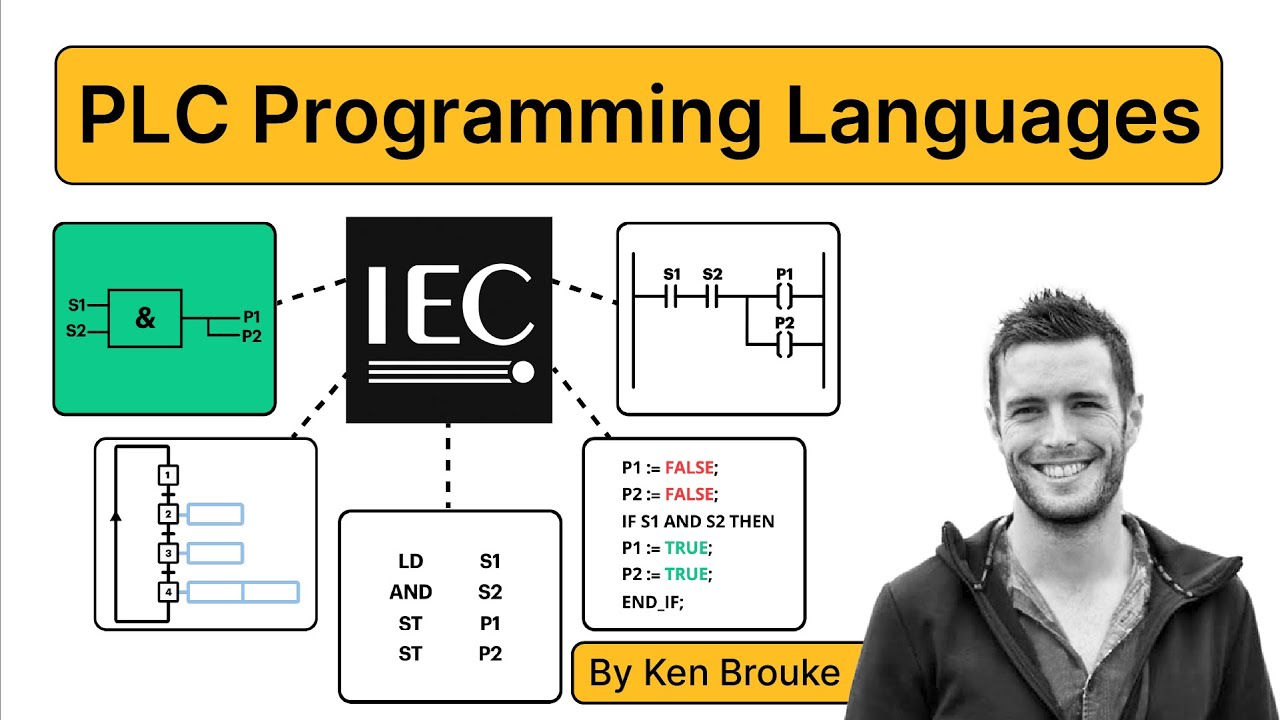

In this article, we will explore the main features, strengths, and weaknesses of the five IEC 61131-3 programming languages. These languages are widely used in the PLC programming world and understanding their differences can help you decide which language to focus on first.

Contents

Ladder Diagram (LD)

Ladder Diagram is the most commonly used PLC programming language. It is high-level and graphical, designed to be easy to read and maintain. Many companies prefer engineers who can program with Ladder Diagram, especially in North America. Each line of code in a Ladder Diagram is a rung, and logic is represented by the interconnection of rungs. The graphical nature of Ladder Diagram makes it easy to debug the logic, even for non-programmers.

Function Block Diagram (FBD)

Function Block Diagram is another graphical language used in PLC programming. In FBD, function blocks are placed on a sheet and connected to one another. This creates a visual representation similar to a Piping and Instrumentation Diagram. The advantage of FBD over Ladder Diagram is that outputs from one function block can easily flow into the next or be used as feedback. This makes FBD ideal for controlling continuous processes where analog values need to be monitored and adjusted.

Structured Text (ST)

Structured Text is a text-based programming language for PLCs. It is popular among younger PLC programmers who are comfortable with text-based languages like Python. Structured Text is powerful for performing complex arithmetic operations and looping over data structures. However, it is often considered more challenging for maintenance engineers to understand and debug.

Sequential Function Chart (SFC)

Sequential Function Chart is a flowchart-like language used to build state machines and sequencers for processes. It is easy to design, monitor, and debug at runtime. Each state is represented by a block, and actions and conditions are defined for each state transition. SFC is suitable for defining high-level state machines and sequencers, with the actions typically written in Structured Text.

Instruction List (IL)

Instruction List is an obsolete programming language similar to assembly language. While it may be encountered in maintenance roles, most manufacturers recommend not using Instruction List for new projects.

Understanding the strengths and weaknesses of each programming language will help you choose the right language for your project. Remember, to become a complete PLC programmer, it is important to be proficient in multiple languages. This allows you to use the optimal language for each application.

If you want to dive deeper into PLC programming using IEC 61131-3 programming languages, check out the CODESYS 1: Introduction to PLC Programming course. This course will teach you how to write your first PLC program using the Ladder Diagram language.

Now that you have an overview of the different PLC programming languages, you can confidently choose the language that best suits your needs. Happy programming!