Are you interested in understanding the intricacies of closed vessel level measurement using a Differential Pressure (DP) Transmitter? In this article, we will delve into the second part of our two-part series, where we explore the process of predicting DP transmitter outputs for open vessel control loops and introduce you to the world of closed vessel level measurement.

Contents

Understanding Open Vessel Level Measurement

In our previous video, we discussed open vessel level measurement using a DP Transmitter. To recap, we learned that the pressure in inches of water can be determined by multiplying the relative density of the liquid with the height of the liquid surface in inches. Additionally, we explored how to convert this pressure value into various pressure scales such as psi, kPa, or bar. However, this method works effectively only when the liquid in the vessel is water.

The Challenge with Closed Vessel Level Measurement

What if the liquid stored in the vessel is not water and doesn’t have a relative density of 1? In most cases, the relative density of liquids changes with temperature. However, for the sake of simplicity, we will disregard the effect of temperature for now.

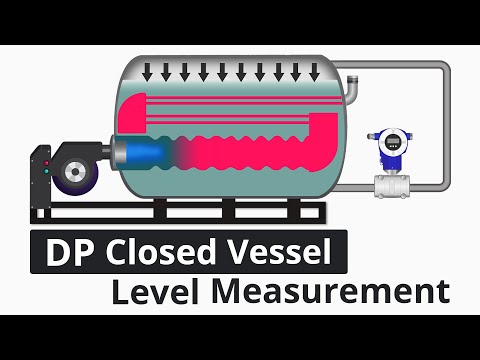

When it comes to closed vessel level measurement, the major difference lies in the need to consider the pressure exerted by the vapor above the liquid surface. This vapor pressure exerts a force on the liquid, which affects the accuracy of the measurement.

Compensation with a Reference Leg

To compensate for the vapor pressure in closed vessels, we must connect the low-pressure side of the DP Transmitter to the top of the vessel through a pipe known as a “Reference Leg.” This reference leg can either be dry or filled with a liquid.

In a dry leg system, the vapor pressure is applied to both the high-pressure and low-pressure sides of the DP Transmitter. The pressure applied to each side essentially cancels out, resulting in an accurate measurement.

However, there are instances when a wet leg system is necessary. This occurs when the reference leg needs to be filled with a fluid, which helps prevent measurement errors caused by vapor condensate in the reference leg.

Predicting Differential Pressure in a Wet Leg System

In a wet leg system, predicting the resulting differential pressure is not as straightforward as in an open vessel or dry leg system. This is because the liquid in the vessel is usually different from the liquid in the wet leg.

To summarize, here is what we have learned so far:

- Liquid relative density and temperature significantly affect DP Transmitter level measurements.

- Closed vessel level measurement requires compensation for vapor pressure.

- A dry reference leg cancels out the vapor pressure on both sides of the DP Transmitter.

- A wet leg system uses a reference leg filled with a liquid different from that in the vessel.

FAQs

Q: I’m new to RealPars. How can I access your online courses?

A: As a newcomer, you have free access to one of our online courses. Simply download the RealPars app and select the first lesson of the PLC Hardware course to get started. Our lessons are renowned for their high quality and ease of understanding.

Q: Are there additional courses available for me to explore?

A: Yes! For a low monthly fee, you can access our exclusive library of courses on PLC programming and industrial automation topics. We also release fresh new videos on a weekly basis, offering you a wealth of knowledge that is not available anywhere else on the internet.

Conclusion

Closed vessel level measurement using a DP Transmitter is a fascinating field that requires careful consideration of various factors, including liquid relative density, temperature, and compensation for vapor pressure. By understanding the principles and techniques involved, you can enhance your expertise in the world of technology and engineering.

For more insightful articles and comprehensive guides, stay connected with Techal, your go-to source for all things technology.